Field Testing – Building Enclosure Commissioning

Field test following the AAMA 501.2 “Quality Assurance and Diagnostic Water Leakage Field Check of Installed Storefronts, Curtain Walls, and Sloped Glazing Systems” procedure.

We perform two types of building testing: in the real world and in the virtual world. For the latter, please see the our webpage dedicated to computer simulations. We perform and witness physical tests in the field to identify potential deficiencies and their sources. We normally follow procedures established by major industry associations and Florida Building Code. We also develop custom tests and modify the equipment to address specific field conditions.

The most typical tests include:

-

- Thermal imaging of building envelope assemblies, by ASTM C 1060 “Standard Practice for Thermographic Inspection of Insulation Installations in Envelope Cavities of Frame Buildings,”

- Water and air tests for diagnosing cladding and fenestration leaks:

- ASTM E1105 “Standard Test Method for Field Determination of Water Penetration of Installed Exterior Windows, Skylights, Doors, and Curtain Walls”,

- ASTM E783 “Standard Test Method for Field Measurement of Air Leakage Through Installed Exterior Windows and Doors,”

- AAMA 501.2 “Quality Assurance and Diagnostic Water Leakage Field Check of Installed Storefronts, Curtain Walls, and Sloped Glazing Systems,”

- ASTM E1186 “Standard Practices for Air Leakage Site Detection in Building Envelopes and Air Barrier Systems” bubble gun test to verify integrity of air barriers and weather resistive barriers.

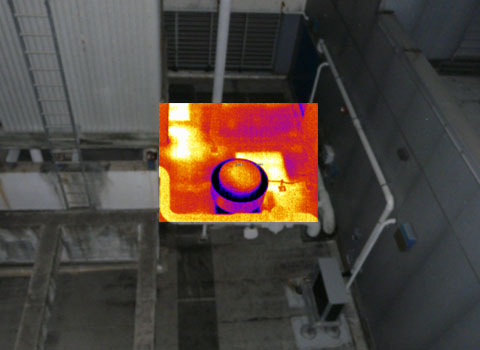

- Thermal imaging for wet materials, insufficient or wet insulation, and air leaks, following the ASTM standard C1153, titled “Standard Practice for Location of Wet Insulation in Roofing Systems Using Infrared Imaging,”

- Hydrostatic pressure (flood) tests for roofs and waterproofing ASTM D5957 “Standard Guide for Flood Testing Horizontal Waterproofing Installations,” leak testing,

- Hydrostatic pressure tests for storm drainage and other plumbing leaks following IBC and FBC plumbing code, pressure testing,

- Wind field uplift resistance tests for hurricane winds following TAS 114 and 124,

- Non-invasive roof wetness evaluation using capacity, infrared, and nuclear testing,

- Glass evaluation and measurements of scratches and other potential blemishes and deficiencies,

- Window and door framing evaluation and measurements for straightness and other potential deficiencies.

- Air leakage tests using “blower door” fan pressurization ASTM E779, and ASTM E 1827 “Standard Test Methods for Determining Airtightness of Buildings Using an Orifice Blower Door,” air test,

- Theatrical smoke tests for air and water leaks,

- Acoustic tests for air and water leaks, tightness testing,

- Borescope (narrow scope camera) investigations of concealed spaces such as the air gap behind cladding (also including sewer camera tests).

- Sealant pull tests by ASTM C1193 “Standard Guide for Use of Joint Sealants,”

- Coating pull tests by ASTM D 4541 “Standard Test Method for Pull-Off Strength of Coatings Using Portable Adhesion Testers,”

- Glass VLT and SHGC measurements in the field,

- Monitoring and datalogging of psychometric conditions, weather condtions, and moisture content over a period of time,

- Magnetic Field Measurements.

We also expanded our in-house laboratory to perform the following types of tests:

- Water Content Determination of Construction Materials

- Salt Resistance of Construction Materials

- Spectrophotometric (UV-VIS-NIR-IR) Testing of Materials.

- Adhesion strength of adhesives and coatings.

The picture below shows the field test following the ASTM standard C1153, titled “Standard Practice for Location of Wet Insulation in Roofing Systems Using Infrared Imaging.” The heat stored in wet roof insulation can be detected after sunset with the infrared equipment, identifying construction defects, failures, and damage:

Condensation Risk Assessment

Condensation Risk Assessment Facade Access

Facade Access Facade Engineering. How To Design a Functional Building Enclosure

Facade Engineering. How To Design a Functional Building Enclosure Facade Impact Resistance Manual

Facade Impact Resistance Manual Foggy Glass Disease

Foggy Glass Disease How To Write and Read a Forensic Report

How To Write and Read a Forensic Report Movements and Tolerances

Movements and Tolerances Review of Curtain Walls, Focusing on Design Problems and Solutions

Review of Curtain Walls, Focusing on Design Problems and Solutions Transitions: How to Design Facade Interfaces

Transitions: How to Design Facade Interfaces When You Need A Window – Solar Design

When You Need A Window – Solar Design

Leave a Reply

You must be logged in to post a comment.