Building Enclosure Consulting

Facade Diagnostics

We are an independent consulting and diagnostic architectural engineering company devoted to sciences and technology of building enclosures. Here is the link to our main website.

Facade Diagnostics

We are an independent consulting and diagnostic architectural engineering company devoted to sciences and technology of building enclosures. Here is the link to our main website.

Computer Modeling and Simulations

We assist designers and attorneys in analyses and presentations of physical processes before or after these processes occurred in buildings. We offer a variety of computer simulations addressing various aspects of building performance, such as thermal, moisture, optical, solar, daylight, acoustic, and air (wind) movement.

You most typically ask us to provide thermal analysis of the curtain wall, because we are recognized as a world-class leader in the field of 3 dimensional computer simulations. Many of these state-of-the-art services are unique worldwide. We are a direct provider, which explains why our prices are low and quality is high. Feel free to add a markup if you are a re-seller.

Why 3d modeling? The world is 3 dimensional, have you ever seen a 2 dimensional building? No, 3 dimensional buildings fill our towns and cities, and the 2 D flatness turns out to be no longer sufficient in heat transfer analysis of the sophisticated architecture. People seem to be accustomed to 3-d buildings and 3-d objects, and architects recently began to model 3 d dimensional shapes in computer graphics programs. No wonder, two dimensional application of computer simulation is no longer sexy.

We also get dirty and provide thermal survey in the field with infrared photo images photo obtained via differential scanning with a thermal imager.

Below is the video commercial describing our services:

Although not all our work results are documented in writing, reports generally give a good example of what we do:

All identifying information was blacked out.

Comments Off on Sample Reports

The dew point meter in the exploratory opening and in the exterior wall affected by high humidity damage to interior millwork

It’s not always rain leakage, we find in our investigations as facade doctors. We sometimes find no traces of water intrusion, as opposed to water condensing inside, where it can damage moisture-sensitive materials, and contribute to microbial growth i.e. mold and mildew. In such a case, (Read the rest of this entry…)

Freeze-thaw failure of decorative rod connections on a brand new aluminum curtainwall facade. The defect affected approximately 10,000 connections.

One of the chief reasons of weatherproofing failures of facades is the thermal stresses and associated movements in excess of seals’ elastic capacity. This is particularly true for metal curtain walls, because of (Read the rest of this entry…)

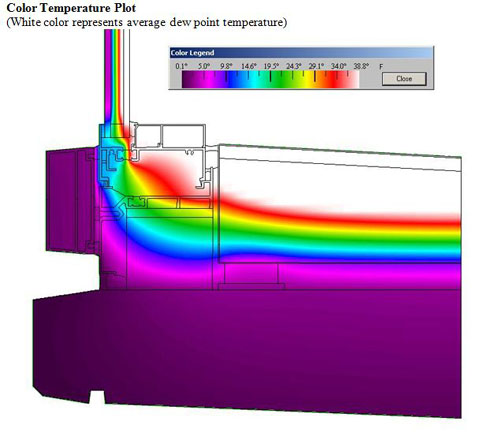

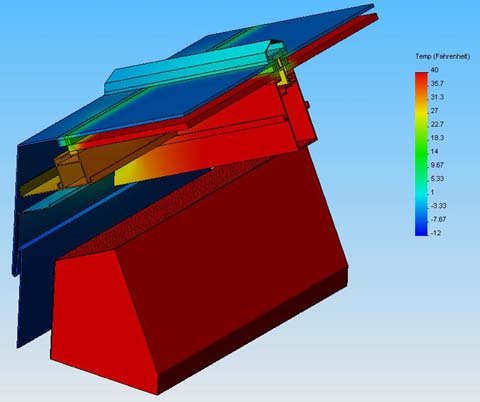

3D thermal simulation of a skylight eave allows for verification of risk of frosting drainage paths. Skylight system designed, researched, engineered, and drafted by Kaz. Cleveland Museum of Art, Cleveland, OH, 2005

We assist designers in verification of performance of bespoke components and assemblies via computerized finite element analysis (FEA): thermal, hygrothermal, optical, solar, static, and dynamic. Many of these state-of-the-art computer generated analysis are unique worldwide. E.g., we are recognized as a world-class leader in the field of 3-dimensional computer simulations.

Download the printable scope of simulation services. (PDF, size 109 kB)

![]()

We not only conduct finite element (FEA) thermal simulations, but also validate them and investigate failed assemblies in the field by thermovision. This kind of analysis provides useful information about temperature differentials reflected from surfaces of analysed materials. In turn it can tell us about any air leakages, thermal bridging, and water content of building envelope assemblies. We sometimes couple infrared images with blower doors, in order to identify a hard-to-detect leakage. (Read the rest of this entry…)

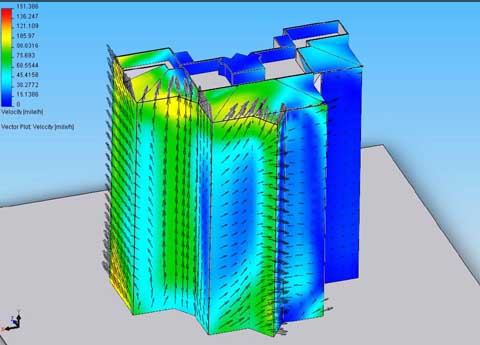

Sample of Computational Fluid Dynamics Analysis

What is computational fluid dynamics? These simulations are performed as a virtual wind tunnel analysis (e.g. for shape optimization or tracing wind-borne projectiles) or for identification of boundary conditions for thermal analysis.

One-dimensional Transient Hygrothermal Analysis. Would there be a water damage inside, at the absence of any rain intrusion or plumbing leaks? Microbial growth? We found the answer in many cases is yes.

These analysis are performed in design stages, in order to assess the moisture behavior of very simple assemblies. Most typically performed to assess the need and location of vapor retarding layers.

We also perform a long-term hygrothermal monitoring of assemblies in the field, in order to identify sources of moisture damage after the possibility of leakage has been ruled out.

You may also be interested in reading the following technical publication:

Condensation Risk Assessment (PDF, size 3 MB) by Mr. Karol Kazmierczak – The Construction Specifier 10/2007

What kind of shade would you prefer to have over your head in the oppressively hot and sunny South Florida? Many people choose their umbrellas (at the absence of rain). Solar energy may not be enough to run my photo voltaic system, but it is powerful enough to cause serious sunburns.

Playing with aesthetics of miscellaneous facade expressions, you might have quickly discovered that screens and shades are tremendously flexible tools, which allow you to carve and paint your facade almost entirely independent from the core. The trouble they are seldom covered by the budget. Not unless you can make a good case for them.

Wouldn’t it be nice to have a dollar tag attached to each exterior shade iteration, illustrating the associated energy savings? This kind of economic justification may find a readier response from the owner, particularly, if you are an architect, trying to justify your facade design.

What did you first notice on this photograph? If you are a sad individual like me, you noticed the condensation on the glass, which obstructs the view of the yellow wings and the black belly of the tit outside. This photo shows two environments inhabited by the tropical bird one one side, and the winter bird staring at each other, separated by the architectural glazing. A small miracle caused by the human intervention in the nature, and on the engineering side by the mechanical system delivering heat and the building envelope containing the heat. The glazed partition conducts heat well, which warms the bird on the exterior, but chills the bird on the interior at the same time. Water condenses on the cool interior surface of the glass, dehumidifying the air adjacent to the window. Such a condensation inside is one of the most common problems with building enclosures in a winter. It wouldn’t have happened if the window was specified correctly and verified by simulations or testing.

3D Static Structural Engineering Simulations are performed for verification of stresses in the material or assembly.

Below is an example of an exaggerated deflection of the curtain wall mullion receiving reaction from the roof above.

Using 3D Thermal Modeling to Improve Performance Requirements by Mr. Karol Kazmierczak – JBED 2/2010

2-Dimensional Steady State Thermal Analysis is performed on simple assemblies to identify the thermal transmittance (U value) and assess the condensation risk. What is the thermal transmittance? It’s composed of the three modes of heat transfer: thermal heat conductivity, thermal heat conductivity, and radiation thermal. It’s often expressed as U values (for windows, curtain walls, skylights, and other glazing).

These NFRC-compliant simulations are nationally accepted as an alternative of the expensive laboratory testing of fenestration. Also, this type of analysis can yield SHGC of the fenestration (measure of solar direct gain in windows) , with the popular software we use.

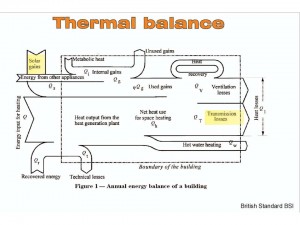

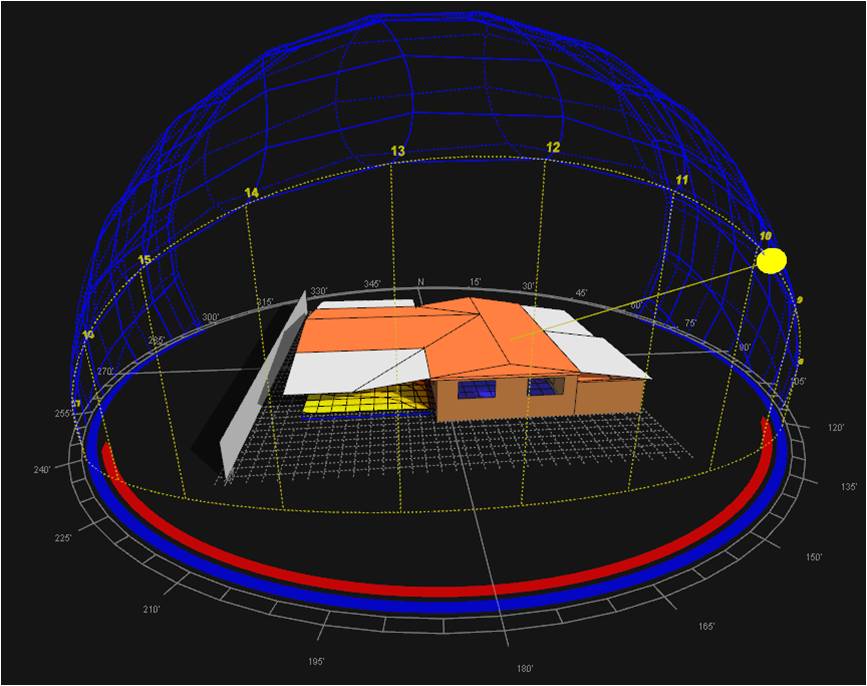

Whole Building Energy Modeling is the energy analysis to estimate the building energy use. It’s often performed for the comparative analysis of design trade-offs to meet the predefined energy goals. Also, it’s an important part of the energy rating process, particularly when combined with the air tightness verification in the field. Required by many energy conservation building codes for energy trade-offs. Energy modeling and simulation is an absolute must for the green building and more generally for energy efficient houses.

How much energy can you save by adding exterior shading? What would be the return on investment on a better window? How about adding a shaded patio? Wouldn’t it get too dark inside? The only way to find out is to simulate these alternatives ahead of time, because the same component would perform differently in different buildings.

These analysis are performed for identififcation of comparative energy impact of individual components of a building. Also helpful in design of passive energy houses, taking advantage of passive solar heat.

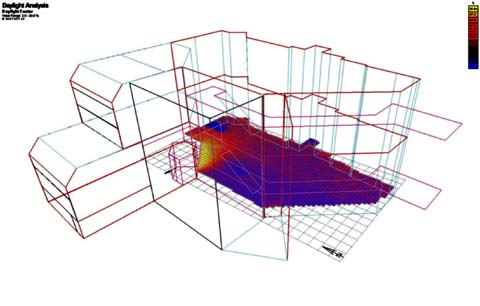

Would it be too dark in the working spaces? Would prison guards be blinded by glare from windows precisely when inmates are out?

We never loose the primary function of glazing from sight: letting the natural light in.We perform daylight simulations and illumination studies to verify the daylight factor. Particularly useful in verification of compliance with the LEED credit 8.1 requirement.

Make your green building more sustainable! Optimize use of natural day-lighting to increase comfort, and minimize artificial lighting!

Glass is seldom matched properly, as seen on the photos below, and therefore owners often require a blanket glass replacement, after only few pieces have been broken or scratched.

Save hundreds of thousands of dollars which would otherwise be spent on replacement of the intact old glass not matching the new replacement glass. (Read the rest of this entry…)

3-Dimensional Transient Thermal Analysis are performed to assess the passive solar design with materials of large heat storage capacity or to assess the condensation risk. Useful in analysis of 3D assemblies made of high-heat storage capacity materials, such as masonry and concrete precast. Would they store and release enough heat to ride through the cold winter night? Would they absorb enough heat to ride through the hot sunmer day?We would give you the answer.

You may also be interested in reading the following free technical publication: Using 3D Thermal Modeling to Improve Performance Requirements (PDF, size 353 kB) by Karol Kazmierczak – JBED 2/2010

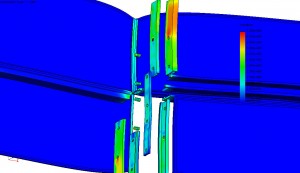

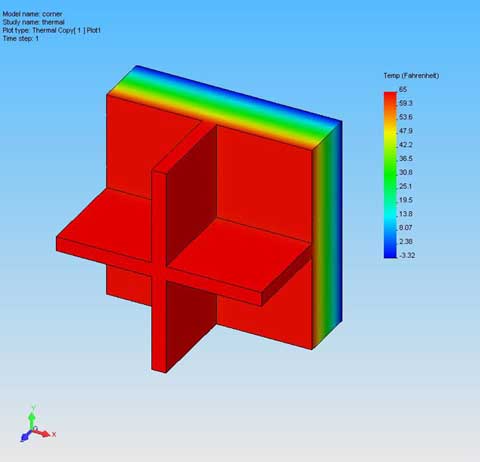

3-Dimensional Steady State Thermal Analysis are performed chiefly to assess the condensation risk of those details that escape the 2D representation, such as shading brackets, anchors, and framing intersections in verification of impact of thermal bridging caused by components penetrating the heat-control layer in two directions.

The image above shows the Sample 3-Dimensional Steady State Thermal Analysis, revealing the thermal (Read the rest of this entry…)

![]()

Consulting architects, I often get surprising elementary questions. Building architecture design of glass houses resulted in careers for consulting engineers occupied full-time by 3-d modeling heat transfer, while some facade architects still ask why double glazed windows or doors are required by building codes.

Here are some frequently-asked questions: (Read the rest of this entry…)

This article is about building construction, and more specifically about application of the finite element analysis to heat transfer and energy sources design analysis of glazing by a consulting architect engineer.

The growing performance requirements introduced gradually in building codes or accepted voluntarily in order to achieve a recognized certification (e.g. LEED) force architects to include engineering in the early phases of the architectural design to address potential vulnerabilities and efficiencies of the design. “Using 3D Modeling to Improve Performance Requirements” by Kaz is the feature article of the Summer 2010 edition of the Journal of Building Enclosure Design (JBED). (Read the rest of this entry…)

We are sometimes asked to simulate or test assemblies, in order to verify whether the inferior specifications are met. It’s always awkward for us to volunteer to identify the engineering question actually worth answering, or to actually respond to the question no-one have asked. For the benefit of those specification writers who are still on speaking terms with us, below is a simple overview of thermal simulations’ applicability:

Generally speaking: